|

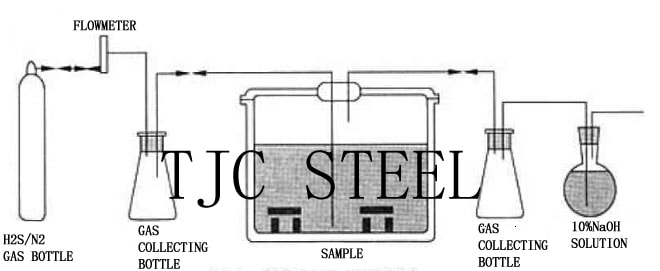

HIC is short name for Hydrogen Induced Cracking.Hydrogen sulfide is one of the most corrosive and harmful media in petroleum and natural gas. In the process of natural gas transportation, hydrogen sulfide plays a significant role in the stress corrosion of the pipeline.When used in wet HYDROGEN sulfide environments, hydrogen bubbling-induced (HB), hydrogen-induced cracking (HIC), and stress-oriented hydrogen-[SCALE STEEL]induced cracking (SOHIC) can occur within carbon steels [1].When hydrogen from corrosion penetrates into steel in acidic environment such as hydrogen sulfide, the crack of pipe is called hydrogen induced cracking (HIC). The NATIONAL standard GB/T8650-2006 Assessment Method for Hydrogen-Induced Cracking of Pipeline Steel and Pressure Vessel Steel specifies HIC assessment method for pipeline steel and pressure vessel steel due to hydrogen absorption due to corrosion in a corrosive environment containing sulfide solution [2].The test method for evaluating hydrogen cracking resistance of NACE TM 0284 pipeline and pressure vessel is specified in HIC. Introduction Hydrogen induced cracking (HIC) is also known as cracking.Hydrogen sulfide is one of the most corrosive and harmful media in petroleum and natural gas. In the process of natural gas transportation, hydrogen sulfide plays a significant role in the stress corrosion of the pipeline.When used in wet HYDROGEN sulfide environments, hydrogen bubbling-induced (HB), hydrogen-induced cracking (HIC), and stress-oriented hydrogen-induced cracking (SOHIC) can occur within carbon steels.In acidic [SCALE STEEL]environment such as hydrogen sulfide, the crack caused by hydrogen penetration into steel caused by corrosion of pipe is hydrogen induced cracking (HIC). The NATIONAL standard GB/T8650-2006 Assessment Method for Hydrogen-Induced Cracking of Pipeline Steel and Pressure Vessel Steel specifies HIC assessment method for pipeline steel and pressure vessel steel due to hydrogen absorption due to corrosion in a corrosive environment containing sulfide solution.The test method [SCALE STEEL]for evaluating hydrogen cracking resistance of NACE TM 0284 pipeline and pressure vessel is specified in HIC. Classification 1) Hydrogen embrittlement: After the hydrogen atoms produced under various circumstances penetrate directly into the steel, the atomic binding force between steel grains will be reduced, resulting in the reduction of the steel's extensibility and end surface shrinkage, and the change of its strength.The cathode reaction corresponding[SCALE STEEL] to the anodic reaction occurs at the crack tip.Hydrogen cracking occurs when the hydrogen produced or processed enters the steel. 2) Hydrogen corrosion: Hydrogen reacts with carbides in steel to produce methane. Methane gas cannot be diffused from the steel and concentrates in grains to form local high pressure, resulting in stress concentration and resulting in microcracks or bubbling of the steel. Damage In the petroleum and natural gas industry and petrochemical industry, if carbon steel or low alloy steel is used in the wet H2S environment, the steel plate will undergo severe embrittlement. The mechanism of this embrittlement [SCALE STEEL]is that H2S corrodes the steel surface to produce hydrogen, which is then absorbed by the steel and causes hydrogen embrittlement.For low alloy steels, this failure can be classified into the following types: 1) Hydrogen-induced cracking (HIC).The HIC does not require stress to generate and propagate within the steel. 2) Sulfide stress cracking (SSC).SSC mainly occurs in areas with high hardness, such as the weld zone. 3) Hydrogen-induced cracking (SOHIC) in the stress direction.In fact, SOHIC can be seen as the result of a combination of HIC and SSC. 4) Hydrogen induced delayed crack: During the welding process of the container, water or oil in the welding material is decomposed [SCALE STEEL]under the action of high temperature of arc to produce hydrogen. Part of this hydrogen enters into the molten weld metal, and when the weld cools, it does not quickly diffuse out, forming local high pressure and leading to the occurrence of micro-cracks in the weld. Test Methods And Procedures Test Plan Test Standard The Test Cycle HIC Hydrogen Embrittlement Test Standard:NACE TM0284-2011,GB/T 8650-2006 Test Cycle:Eight days Test Medium: Solution A: Sodium chloride acetic acid solution containing saturated hydrogen sulfide at room temperature and pressure Solution B: Artificial seawater containing saturated hydrogen sulfide at normal temperature and pressure Recommended Size Of Sample: 100mm*20mm* Actual thickness (30mm) Test Evaluation: The crack sensitivity ratio CSR Crack length ratio CLR Crack thickness ratio CTR Schematic Diagram Of Hic Hydrogen Cracking Test Sample size: 100mm long, 20mm wide.

1) Thickness <30mm: parallel sampling: take 1 group of samples of the same product and the number is 3; 2) 30mm≤ thickness <88mm: step [SCALE STEEL]sampling, take 1 group of samples of the same product and the number is 3; 3) Thickness ≥88mm: step sampling, 1 sample thickness <30mm, the maximum number of samples according to the actual thickness Comments are closed.

|

nEWSFROM SCALE STEEL ARCHIVES

July 2024

Categories |

RSS Feed

RSS Feed